Used Welding positioners

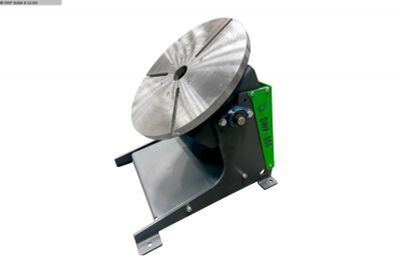

Welding rotary tables are special tools used in metalworking to rotate workpieces during welding. They are usually round or rectangular and can accommodate different weight classes depending on their size and application.

The welding rotary table has a horizontal turntable driven by a motor. The speed of rotation can be regulated as needed. The workpiece is fixed on the turntable and rotated around its own axis by turning the table to produce a uniform weld.

Welding turntables are usually equipped with a foot pedal or hand switch that allows the welder to control the rotation speed and stop or rotate the workpiece to achieve precise positioning. They are commonly used in the fabrication of pipes, tanks, vessels, steel structures and other large metal parts that require a precise weld.